Taipei International Machine Tool Show (TIMTOS)

Topic 1: Precision Processing

To enable the audience to have a basic concept of precision machining, the guided tour on the first day of TIMTOS was arranged for a number of representative manufacturers of precision machining machines to guide. By understanding their development, and how to respond to changes in the times, technology, and product line layout, you can have a comprehensive understanding of the evolution of the precision machining industry. It can also allow the audience to connect with the guided tour of the next two days: an in-depth understanding of the machine tool ecosystem and the transformation of smart manufacturing.

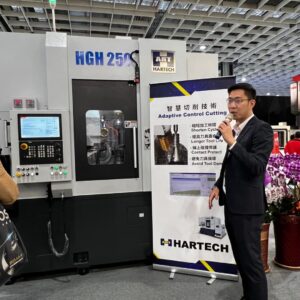

Hota Industrial MFG, since its establishment, has been committed to the improvement of gear production skills. The production of high-precision and high-efficiency gear machinery has always been an important topic for Hota’s technology improvement and development.

Since 2003, Hota has been committed to the research and development of CNC gear cutting machinery. In 2005, the Machinery Division was established. After continuous research and development and strict quality and production testing, it is now marketing globally under the brand of “HARTECH”. : The smart cutting technology of the HGH 250 gear hobbing machine can shorten the processing time, improve the tool life, have online collision protection, and avoid tool damage.

YCM Alliance has accumulated nearly 70 years of professional machine tool manufacturing technology to produce high-rigidity and high-stability professional machine tools. With “ultra-high quality, cutting-edge technology, and all-round service” as its core value, it continues to design and develop high-quality performance and equipment. machine tool. Provide general parts, aerospace parts, automobile and motorcycle parts, mold processing and other applications.

The high-productivity five-axis vertical processing machine NFX400A was exhibited on site. Its high-rigidity structure design, high-precision axial feed design, combined with the self-made high-speed IDD direct-coupled spindle can effectively improve the production capacity of automated production and the stability of processing quality. Its products have passed the ISO 14955 energy efficiency certification. The company also stated that it will continue to improve the performance of its five-axis machines in response to the demand for precision components.

Fair Friend Group started from sawing machines and grinding machines. Because of its insight into the future development of the machine tool industry, it has invested in the development of CNC series products. It currently has 37 machine tool brands and 50 production bases. It is the world’s largest manufacturer of vertical processing machinery.

There is a brand interactive video wall on site, allowing visitors to click to learn about each brand information, and also displaying products of different brands that meet the different needs of customers, and introducing the award-winning product-micro-axis control machine tool and its processing unit. Fair Friend Group Industrial’s smart empowerment is its strategy to achieve green sustainability. Through the design of green machine tools, it is connected to the data service platform. Furthermore, it carries out smart manufacturing services such as manufacturing optimization.

Tongtai has seven major perspectives in the development of smart manufacturing: intelligence, automation, compounding, and service. It continuously develops new processes, serves new industries, and pursues zero carbonization.

The on-site exhibits include vertical processing machines, horizontal processing machines, compound cutting machines, and an upgraded industrial doctor platform, which provides customers with remote product diagnosis, technical support, and automation solutions – combining robotic arms, multi-machine Serial connection, design fixture flow manufacturing plan, achieve highly customized and flexible manufacturing. You can also see the demo with the robot on site.

Wele has been focusing on the development and design of new products for a long time. At present, seven series of products have been successfully launched, including vertical processing machines, horizontal processing machines, high-speed processing machines, large-scale gantry processing machines, large-scale gantry five-sided processing machines, and gantry five-axis Processing machines, large vertical turning and milling machines, etc. Its comprehensive processing machine and its processing unit also won the TIMTOS Excellence Award. The monitoring system of the fully automatic production line can be seen on site. Its modular design allows customers to expand to an automated production line after purchasing the machine.

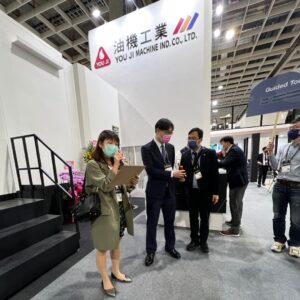

Youji has the most complete models of vertical lathes in the world, and the processing chuck diameters range from Ø200 to Ø8000mm. It is the first vertical lathe manufacturer in Taiwan to pass the certification of European C.E and EMC, and also the first manufacturer to enter the European and American markets. You Ji is the largest vertical lathe manufacturer and exporter in Taiwan. On-site display of large vertical lathes and medium and large vertical turning centers (Vertical Turning Center) VTL1200ATC+C models. This equipment is a high-rigidity, high-precision, high-efficiency intelligent machine tool with a working disc diameter of O1250 mm , with a maximum rotation diameter of O1600 mm, which can meet the large-scale processing requirements of various aerospace engine casings and various high-precision rings.

With excellent turning performance, it is designed with CS-axis dual-spindle motors to provide high positioning accuracy within 8 seconds. , within 4 seconds of repeatability, can perfectly, accurately and quickly complete all kinds of combined turning and milling machining, especially for large, complex, irregular and complex machining workpieces with high precision requirements.