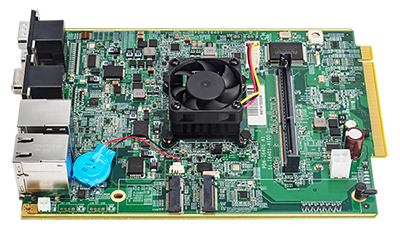

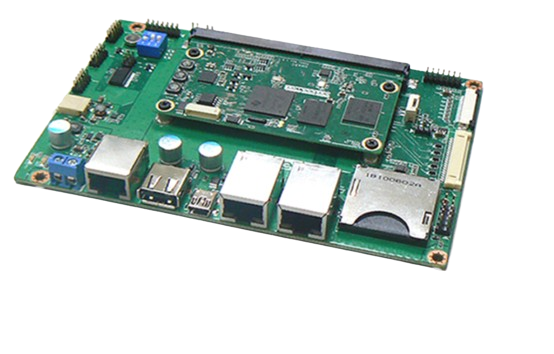

Single Board Computer

In the Industry 4.0 era, single-board computers (SBCs) serve as compact, cost-effective building blocks. They offer high processing power, minimal power consumption, and versatility. Key advantages of using SBCs include enabling edge computing, seamless IoT integration, predictive maintenance, machine learning capabilities, ruggedness for harsh environments, and improved quality control in manufacturing processes. We have both x86 and Arm architecture products that can meet different needs.

Single-Board Computers (SBCs)

A single-board computer is a complete computer system built on a single circuit board. It integrates essential components such as the CPU, memory, storage, and I/O interfaces. Here are some key points about SBCs:

SBCs are compact and space-efficient, making them ideal for applications with limited physical space.

SBCs consume relatively low power, making them suitable for energy-efficient solutions.

Due to their simplified design and integration, SBCs are cost-effective compared to traditional desktop computers.

Despite their small size, modern SBCs offer impressive processing capabilities, often featuring multicore processors.

SBCs can be used for a wide range of applications, from hobbyist projects to industrial automation.

Advantages of Using SBCs in Industry 4.0

A single-board computer is a complete computer system built on a single circuit board. It integrates essential components such as the CPU, memory, storage, and I/O interfaces. Here are some key points about SBCs:

SBCs enable edge computing, where data processing occurs closer to the data source (e.g., sensors, cameras) rather than relying solely on centralized cloud servers. This real-time processing enhances responsiveness and reduces latency.

SBCs facilitate seamless integration with the Internet of Things (IoT) devices. They act as gateways, collecting data from sensors and transmitting it to cloud platforms or local servers.

By deploying SBCs at the edge, manufacturers can monitor equipment health, detect anomalies, and predict maintenance needs. This proactive approach minimizes downtime and improves overall efficiency.

Some SBCs support machine learning applications using specialized hardware (e.g., Tensor Processing Units). These can analyze patterns, detect defects, and optimize processes.

Industrial-grade SBCs are designed to withstand harsh environments, including temperature variations, vibrations, and dust. They ensure reliable operation in factories and production lines.

SBCs with camera recognition capabilities enhance quality control by automating inspections, measurements, and flaw detection.

In summary, SBCs serve as powerful building blocks for Industry 4.0, combining efficiency, connectivity, and ruggedness to drive automation and innovation in manufacturing processes

Netio Technologies

Your Best Design Partner !