Taipei International Machine Tool Show (TIMTOS)

Topic 2: Ecosystem

Understanding the differences & types & functions of machine tools can overwhelm ordinary people. Starting from the perspective of how to form a machine tool may help to understand the whole picture of the metal processing ecosystem. Because of this, the organizer has specially planned four routes for the exhibition this year: controllers, measurement, key components, and punching machines, leading the audience to become familiar with the industrial ecosystem of machine tools gradually.

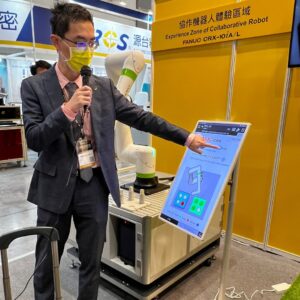

Taiwan FANUC is famous for producing robots and CNC machine tools. It mainly sells FA (Factory Automation) related products, CNC controller systems, servo motor systems, laser oscillator systems, and industrial robots, and provides after-sales maintenance services.

The CRX collaborative robot displayed at the scene not only has a susceptible contact stop function but also can safely cooperate with personnel. It also appeals to an intuitive operation interface and has an automatic hand-teaching function, which can carry out program memory through multi-point movement. Simply put, it is a collaborative robot that appeals to be safer, simpler, and faster.

HEIDENHAIN has a long history of focusing on R&D and production of high-precision and high-quality measuring equipment and CNC controllers and has always been a pioneer in the field of measurement, control, and drive system technology.

The brand-new CNC controller TNC7 was displayed on site, featuring intuition, task orientation, and personalization, providing a new way of operation and programming. Take smart programming that emphasizes intuition as an example, as long as you draw the outline through the touch screen, you can easily and directly convert the graphics into machine tool programs.

Mitutoyo Group, the parent company of Mitutoyo Instruments in Taiwan, mainly produced small measuring tools such as centimeters and vernier calipers in the early days. It has developed into a world-renowned manufacturer of precision measuring instruments and can be said to be an expert in the manufacture of precision measuring instruments.

In recent years, the Mitutoyo Group has devoted itself to the research and development of various measuring instruments based on the concept of unmanned. The types are quite diverse. A full range of measuring equipment can also be seen on site, such as coordinate measuring machines, image measuring machines, and shape measuring machines. , microscope, micrometer, vernier caliper, etc.

Renishaw is a multinational group that started as a touch-trigger probe. It enjoys a high reputation in the field of high-precision measurement technology. Its products are also widely used in industries such as aerospace, automobiles, electronics, precision manufacturing, and healthcare. superior.

The theme of this year’s exhibition focuses on the complete process layout, starting from the three levels of “machine calibration, workpiece production, and quality control” to display related technologies and product applications, to help customers improve production efficiency and maximize profits targets.

YJF Casting is good at producing machine tool castings, machinery, ship engines, large energy castings, etc. with cast iron, and provides a one-stop service from design to casting and processing. As the leading brand of Taiwan’s large-scale foundry, YJF has a complete casting process management system, and carefully checks every link of product manufacturing from the source.

Since the pursuit of ESG sustainable development has become a development trend that cannot be ignored in various industries, Yuan Runfeng also became the first foundry in Taiwan to pass the ISO 14001 (environmental management system) certification in 2006 and is committed to taking into account economic activities and ecological environment. balance. Yuanrunfeng attaches great importance to the environment, which can be seen from the booth layout on site.

YJF’s exhibition hall is only constructed of primary-colored wood, and then decorated with various green plants, giving it a fresh atmosphere. According to the on-site personnel, the reason for choosing unprocessed raw-colored wood as the exhibition material is that it is difficult to use the wood for other purposes after coloring. For the pursuit of energy saving and carbon saving, YJF not only starts from itself but also joins hands with upstream and downstream partners to form the “Low-Carbon Industry Sustainable Development Alliance”.

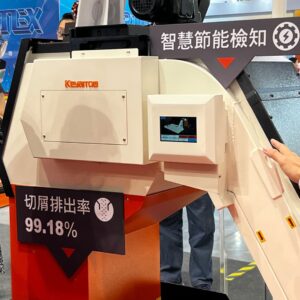

KEYARROW started with the manufacture of precision sheet metal, and later transformed into a professional manufacturer of “machine tool retractable cover”, and established the KEYARROW brand, with the promise of becoming the “key arrow‧key components” of the machinery industry, and is now a machine tool Expert in chip protection systems and chip removal and filtration systems.

With many years of design and manufacturing experience, KEYARROW can be closer to the needs of customers. It always starts with solving the pain points of users, improving existing designs, and adding new functions to products.

CHINFONG is now the largest stamping, forging and forming equipment factory in Taiwan, with the core philosophy of “service first”, “innovation” seeking change, and benefit “return”. Its closed single-crank intelligent punch press (STI-110L) is particularly eye-catching, featuring the integration of 3R (Recycle, Reuse, Reduce) thinking, which can improve structural rigidity, reduce material usage, and simplify parts, and won the 2023 Excellent work award in the 16th Machine Tool “Research and Development of Innovative Products” competition.

LCM Machinery is a professional equipment factory in Taiwan that produces various large-scale hydraulic presses. It has produced thousands of hydraulic presses since its establishment more than 70 years ago, and each one is customized, developed, and manufactured. Lianlian Machinery has a complete and diverse product line, including deep suction hydraulic presses, forging hydraulic presses, mold clamping/testing hydraulic presses, hydraulic forming hydraulic presses, copper foil substrate/printed circuit/composite material lamination equipment, SMC/GMT/BMC hydraulic presses, etc.