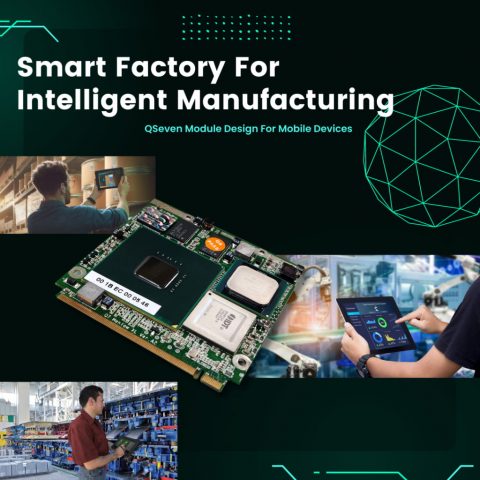

Smart Factory for intelligent Manufacturing- Part 3

Previously in our series of Smart Factory for Intelligent Manufacturing, we elaborated Computer-on-Module (COM) or System-on-Module (SOM) is the most popular and excellent high-performance computing solution for various industrial applications. Besides COM Express form factor for larger systems, Qseven is another form factor for smaller or mobile products/solutions.

Part 2 of Smart Factory Topic.

The name Qseven (Q7) is derived from “quadratic” as noted by the Q and seven refers to the 7 x 7 cm (70 x 70mm) size of the module. With a smaller size footprint mobile processor and chipset. The advantage of Q7 is its low power consumption interfaces for mobile and battery-operated (equal or less than 12W). It also matches the requirements for fan-less operations by heat spreader mechanism. Qseven does not require an expensive board-to-board connector and is capable of high-speed PCI Express Graphic (PEG) data transfers.

Concluding the benefits of a product/ solution implemented Qseven is below,

1. Small- One of the smallest computer-on-module form factors (70 x 70mm).

2. Acceleration- Products and system/ solution teams can focus on core values and deliver a better user experience rapidly.

3. Longevity- Qseven modules are available between 5 to 15 years from launch.

4. Reliable- High reliable performance function and high assessable integration.

5. Rugged- Operation under a wild range of temperatures ranging from -40 to +85°C, waterproof support, and other harsh conditions.

By distributing intelligence and insights to the production floor, mobile devices consolidate information, accessibility, and computing power into a single platform that can give any employee use with minimal training. In a smart factory for intelligent manufacturing, there are some scenarios suitable to deploy mobile device solutions. Inventory management needs a speedier workflow for barcode scanning and inventory updates. Production needs rapid information to monitor downtime, and problems, and to anticipate potential failures.

Nowadays, customer-centric production is where the value chain can flow effectively. That means little tolerance for defects. Versatile mobile devices help ensure manufacturing personnel use augmented reality images to conduct visual quality checks, and train employees to increase the chances of a high-quality final product. As well as the big data technique to facility factory operations, to reduce the risk of a machine failing in every microsecond matters, a mix of cloud and on-premise data processing centers ensures almost zero latency in computing and alerts.

We are dedicated to providing our customer’s tailored service and high-tech information that can benefit the most. We welcome you to subscribe to our NEWSLETTER to catch the latest tech trends! Stay tuned.

Click for more details of Qseven solution :

Smart Factory for intelligent Manufacturing- Part 5

In the previous article of our series, we introduced rackmount computers which can provide an organized working station or stable & high-performance systems.

Smart Factory for intelligent Manufacturing- Part4

To deliver a solution for a variety of smart factory workloads, such as machine automation,

Smart Factory for intelligent Manufacturing- Part 2

The fourth Industrial Revolution (Industry 4.0, aka IIoT, Industry Internet of Things) is here to stay.

Smart Factory for intelligent Manufacturing- Part 1

Technological advancements brought innovations in several industrial fields.

Sign up for our email brief for IPC articles, news, and more.

Netio Technologies

Your Best Design Partner !